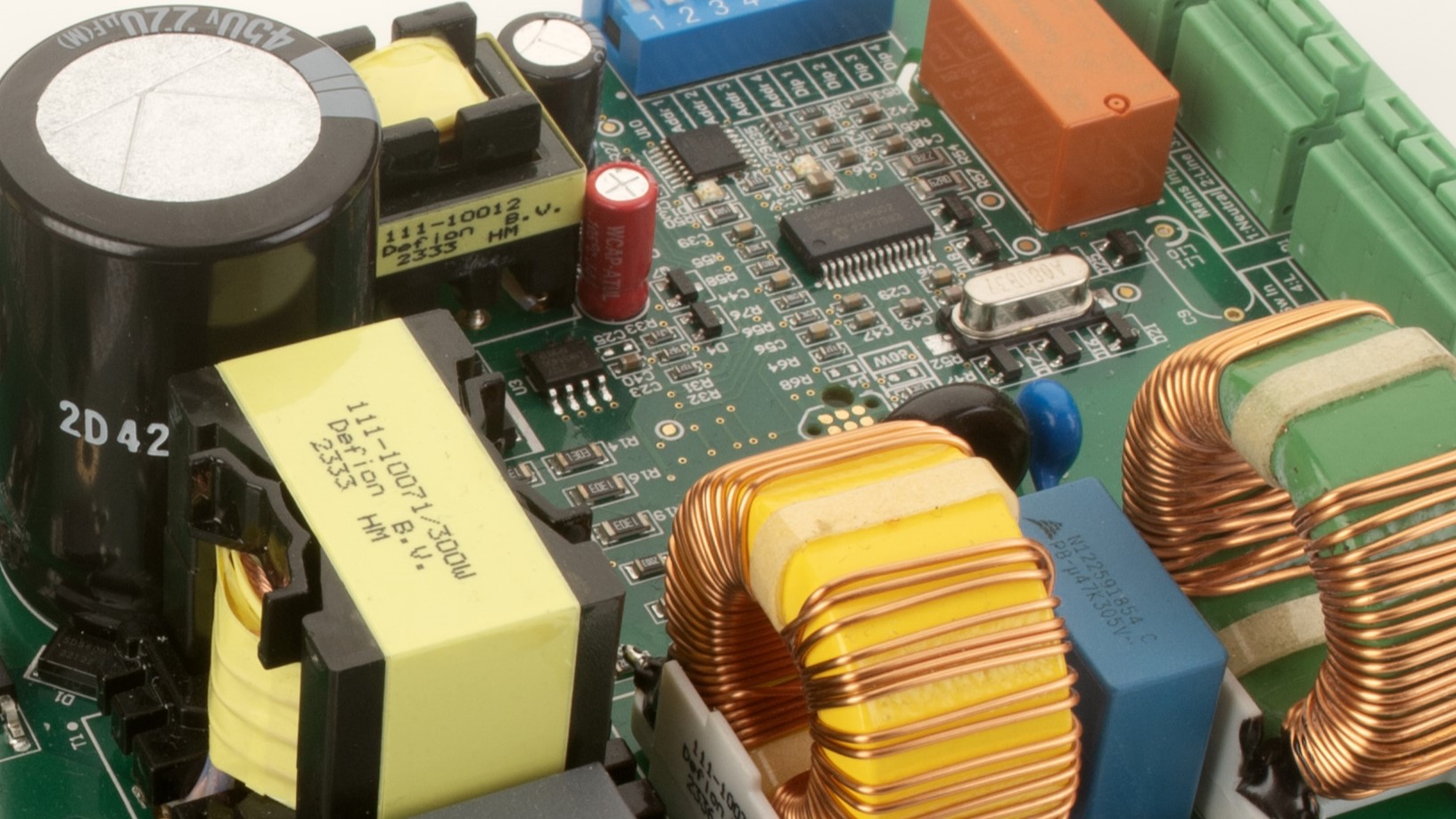

At Defion we are specialized in the development of high quality, often industrial grade, power converters. As a start, we define together a clear specification based on your requirements. Based on this specification, we can develop a early prototypes to validate the design in your application.

Defion is a manufacturer of electrical and electronic devices and or PCBA’s. For any quantity, the applicable supply chain will be set up. With production partners in the Netherlands, Europe or the far East.

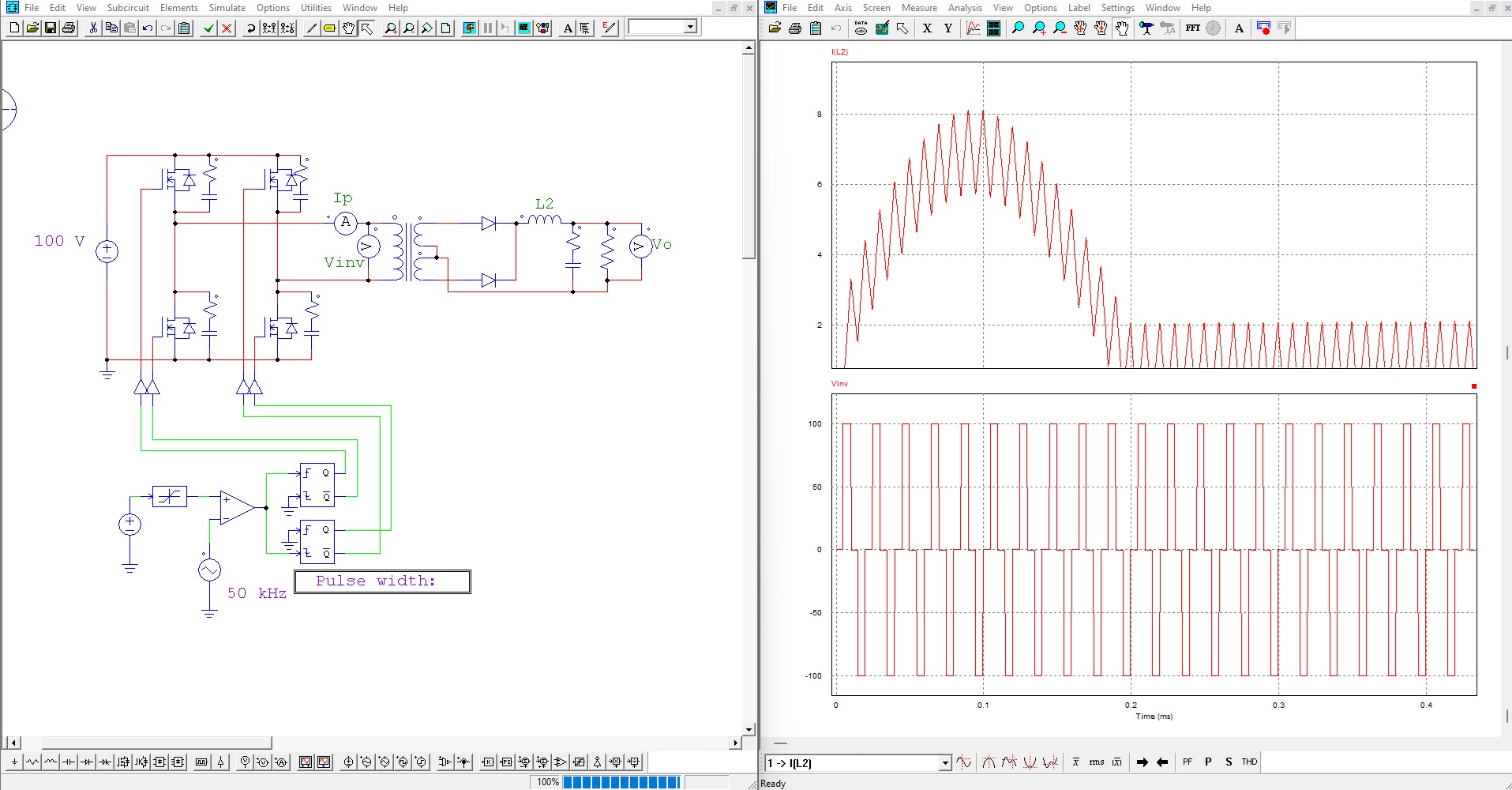

Simulation tools are essential to develop a reliable, compact and affordable product nowadays. We use these tools to validate the electrical and thermal design before the first prototype is produced.

Printed Circuit Boards, PCB’s are designed in house. The PCB is the heart of the design, where the functional behaviour, EMC, thermal and producabilty are all combined. We have the experience to make the design meet all your requirements.

For power electronics custom inductive devices are key to meet the thermal, EMC and mechanical requirements. We develop and manufacture our own custom inductive devices.

Power conversion requires realtime controls. We are experienced in Microchip, ST or TI microchips. It is always possible to integrate with a customer specific platform.

To minimize development time and conduct effective DFM analysis, it’s essential to produce prototypes or initial small production runs in-house. At Defion, we are committed to this approach, which is why we have established a complete SMD production line. Our facilities include a stencil machine, pick and place machines, a reflow soldering machine, and a vapor phase soldering machine.

After the SMD production step, PCBA’s are finalised with through hole parts. After cleaning products are assembled inhouse.

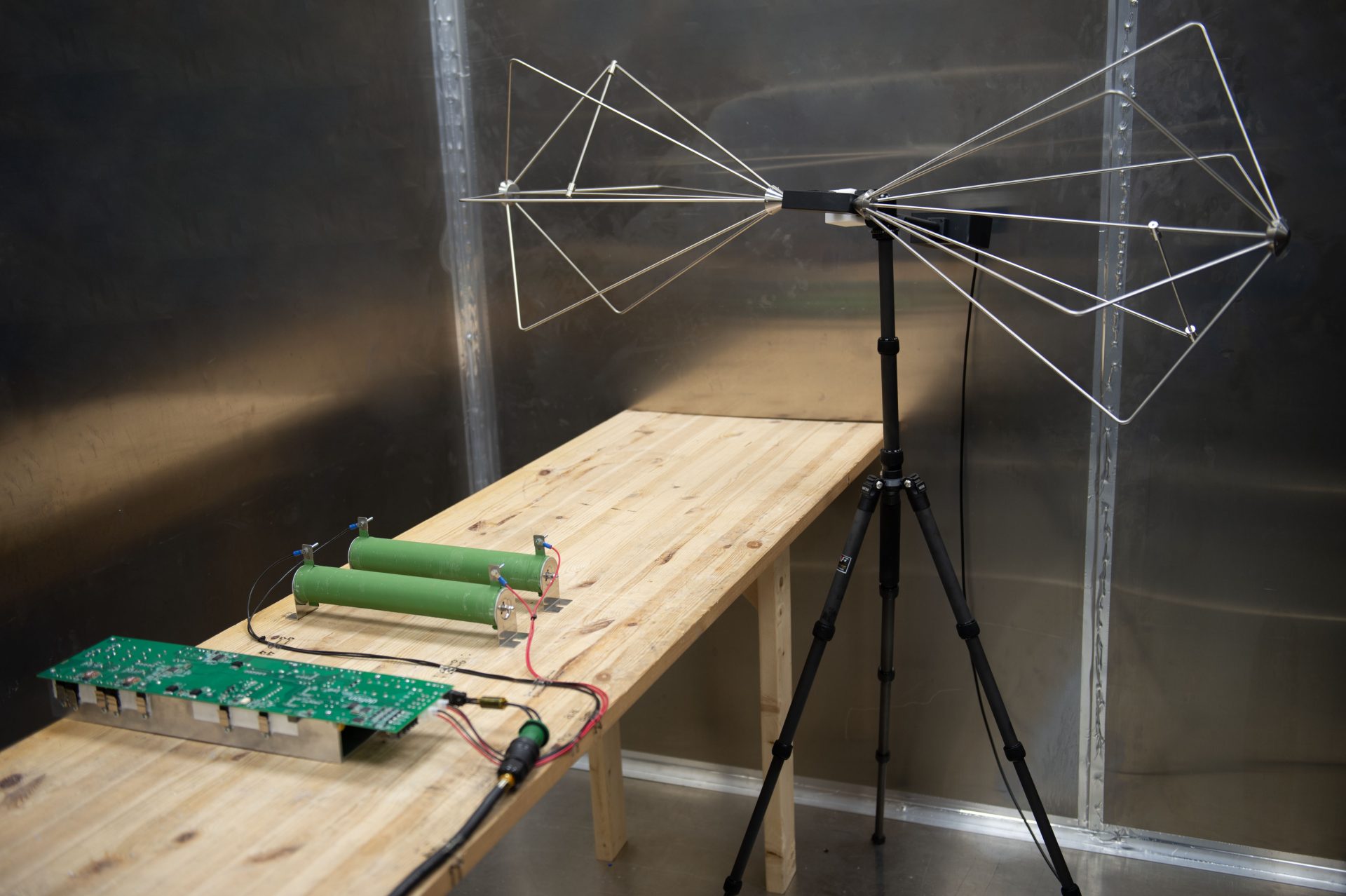

To be able to sell your product in Europe or the United States, the product must meet a stringent set of standards. We consult with the customer where the product will be sold, so we can assess what regulations the product must meet. These regulations primarily describes product safety and electromagnetic compatibility.

Electromagnetic compatibility (EMC), sometimes referred to as Electromagnetic interference (EMI), is applicable for each product. Each product has to comply with the applicable EMC standards. Defion has a pre-compliance measurement setup to verify the product during development. Before release to the market, we can take care or assist in the execution of certification tests at external laboratory.